Products >> sanitary valves >> sanitary ball valves

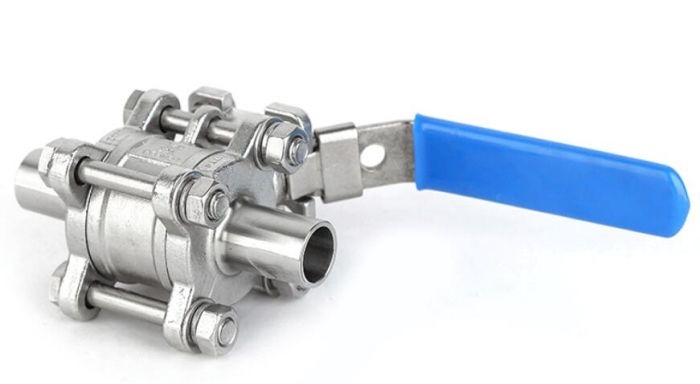

sanitary three pieces weld ball valve

- Product No.:202142812244

Sanitary ball valve for material transportation. The valve's applications include food and beverage processing, sanitary grade ball valves, and is the choice for handling viscous or particulate containing fluids.

A ball with a through cavity is placed between two flanges and two PTFE valve seats in the valve body. A valve shaft core through 90 ° The rotation can act on the ball, thus opening or closing the valve.

At the same time, the valve seat cleaning joint can be added to clean the valve cavity of the ball valve and discharge from the discharge hole.

The ball valve has three structures

Straight through ball valve, three piece structure, composed of two flanges, valve body and two PTFE seats. Install with bolts. The valve seat cleaning joint can be added to clean the valve cavity of the ball valve and discharge from the discharge hole. The three-way ball valve has T-type and L-type structure. It is composed of valve body, valve cover and PTFE valve seat, with thread installation.

Straight through ball valve, two-piece structure, composed of valve body, joint and two PTFE seats, with clamp type installation. Technical options:

Specification: from dn25-1 "to dn 100-4"

Operation mode: manual, pneumatic and electric

Welding, clamp, thread, flange connection (mm or in.)

Working pressure: 10bar

Operating temperature: - 10 ℃ to 120 ℃ (140 ℃ for short period or disinfection)

Part in contact with material: 1.4404/aisi 316L 1.4301/aisi 304

Other stainless steel parts: 1.4301/aisi 304

Internal surface contact product: RA ≤ 0.8 μ m

External surface treatment: polishing, sandblasting

Sealing element: EPDM conforms to FDA 17.2600

Sealing gasket: PTFE, TFM meet FDA 177.1550

Requirements for three piece all inclusive ball valve: [material] SUS304, SS316

[Specification] DIN standard: DN 15-dn 100; ISO standard: Ф 19(0.75s)—— Ф 108(4.25s)

[working principle] sanitary clamp/weld type all inclusive ball valve uses the ball to rotate around the axis of the stem to realize the purpose of opening and closing. The sanitary clamp type quick installation ball valve is mainly used to cut off the flow of medium in the pipeline.

[application] it is specially used in various high corrosive media and other industrial fields.

[note] all sanitary valve fittings are mirror polished in contact with medium.

The opening and closing part of the three piece ball valve is a ball. The ball rotates around the axis of the valve stem to realize the purpose of opening and closing. The three piece quick installation ball valve is mainly used to cut off the flow of medium in pipeline.

The main features of three piece ball valve are reliable sealing, compact structure, easy operation and maintenance. In addition, the fluid resistance of sanitary ball valve is the smallest, and its resistance coefficient is equal to that of the same length of pipe.

Previous Product:sanitary actuator three ways ball valve

Next Product:sanitary three pieces clamp ball valve